Since 1967 "We Supply The Power You Supply The Skill "

Phone: 1-781-857-2500

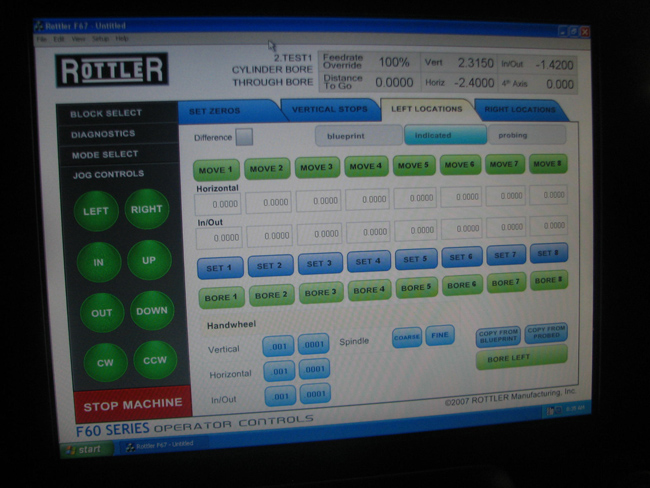

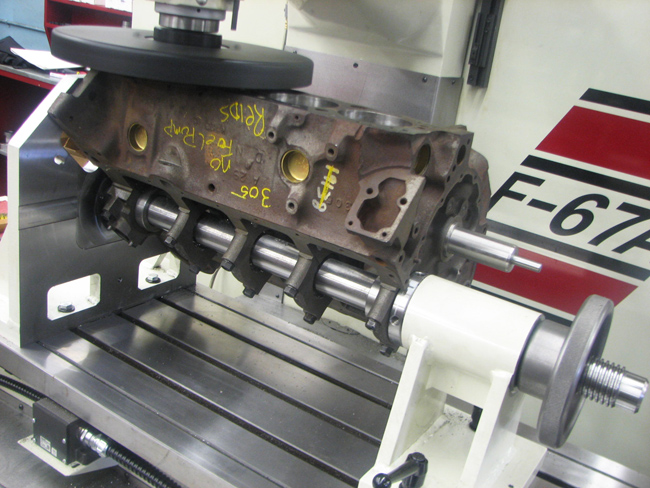

Rottler F67A : CNC Block Blue Printing - Line Boring - Darton Sleeve Installations - Stroke Clearance

Phone:1-781-857-2500

State of the art machining capabilities operated by expert machinists. These machines are specifically designed for High Performance Engine Blue Print machining operations. Custom machine your components 1 part at a time. OEM'S use the Pan Rail as The machining Datum. This is why deck heights are not at a true 90 or equal end to end.Cylinder bore locations and even lifter bore distances and locations are not on Blue Print Spec. Reid's Automotive has invested in Rottler F67A CNC Equipment with 4 th axis and probing processes to correct bore center spacing , deck heights and lifter bore locations. Our fixtures are based from the main line and cam shaft centerline. The process will increase Horse Power while Improving overall Engine Performance. Your Hot Rod, Vintage Restoration, Marine Engine, or Race Engine will perform at peak performance levels.

Reid's Automotive utilizes the best components and machining processes. Reid's Automotive will satisfy even the most demanding requirements because "Quality isn't an option it's a requirement"

Rottler F67A CNC Block Blueprinting Services

Cylinder Bore Blue Printing Process

Note: Precision Locators are Installed in # 1

and # 4 bore housing with cap installed.

Step 2. Precision bar is then installation into the precision main line locators.

Deck Squaring to the main and cam centerline

Boring cylinders main and cam centerline.

Bore center corrected to Blue print specs.

Line boring.

Lifter Bore corrections.

Darton Sleeve Installations.

Services performed on our Rottler F67A CNC

Step 3. Install Precision Cam line Locator and

cam bar.

Step 4. Line up tail stock and 45 degree

datum plate.

Step 5. Indicate datum plate.

Step 6. Input bore location from print.

Note: Save data for block type for use on

future blocks.

Step 7. Load the block and install precision cam and main locators onto the precision locator. The locator bars are then installed into the precision datum plate.

The set up fixture enables all machining to reference the Camshaft and Main Line centerline.

Step 8. The CNC program locates the indicator at the true blueprint location. The operator can accept the blueprint locations or adjust the bore centers for wear or core shift.

Stroker clearance routine.

Block Boring

True to the cam and crankshaft centerline

Block Squaring

True to the cam and crankshaft centerline at true

45 degree angle. decked to the correct deck height.

Lifter Bore Correction

Line Boring Splayed Cap Installation

Darton Sleeve Installation LS-2

Sleeving a "Rare" 427 Ford Block

Darton Sleeve Installation Honda Block

Step 1. Place Precision Locators In Main Line

Sunnen CK-10 Torque Plate Honing Block

Services Pages

Links Below